Metal Powder Solutions

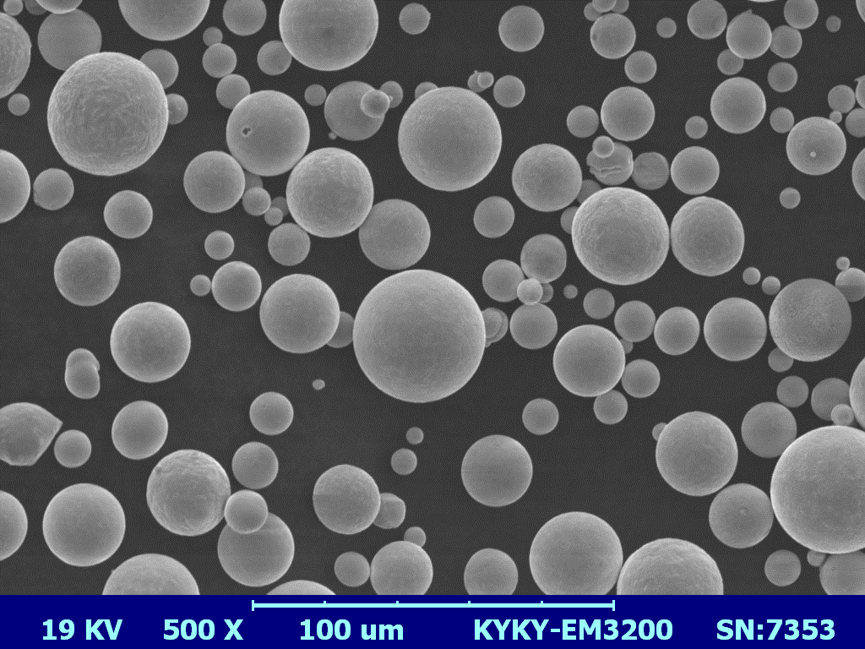

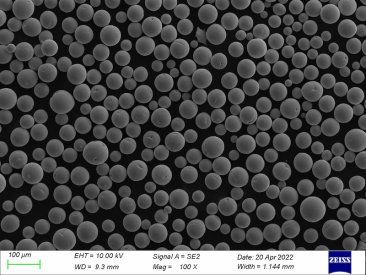

AM / 3D Printing Powders

Custom Metal Powders for the Next Generation of Additive Manufacturing

Our key strength is to work in partnership with every customer to develop custom alloys as per their specific technical requirements – including novel alloys.

Comprehensive Suite of Production Capabilities

With our advanced VIGA, EIGA, PREP and Radio Frequency Plasma Spheroidization technologies, we are able to provide a comprehensive range of engineered metal powders for all additive manufacturing applications.

R&D Engineers / Industry Innovators / Scale Up Partners

Provide us with your powder’s specification parameters and we’ll add value to your supply chain by effectively and efficiently streamlining the powder development for you, allowing you to focus on your other core activities. We can supply small-batch powder samples produced by various atomisation techniques in support of the R&D projects of our customers.

Academia

We frequently partner with University researchers interested in novel metal powders and alloy innovation, supplying research-grade AM materials. Contact us to see how our small-batches can quickly kick start your academic program.

Our Standard Powder Range – Available in Small Batches – Contact us for Customised Requirements

- Spherical Titanium & Titanium Alloy Powders (TiCP Grade 2, Ti64 Grade 5, Ti64 Grade 23, etc.)

- Spherical Nickel Alloy Powders (IN625, IN718, IN939, Hastelloy X, Haynes 230, etc.)

- Spherical Cobalt Alloy Powders (CoCrW, CoCrMo, CoCrMoW, Haynes 188, etc.)

- Spherical Aluminium Alloy Powders (Al, AlSi10Mg, AlSi7Mg, AlSi12, AlSi20, 2024, 5083, 6061, 7075, etc.)

- Spherical Copper Alloy Powders (Cu, CuCr1Zr, CuSn12Ni2, CuNi2SiCr, CuAlNiFe, etc.)

- Spherical Stainless Steel Powders (1.4404, 1.4435, 1.4307, 1.4545, 1.4542, etc.)

- Spherical Tool Steel Powders (1.2344, etc.)

- Spherical Die Steel Powders (1.2709, CX, etc.)

- Spherical Tantalum Powder, Molybdenum Powder & Niobium Powder

Ti64 Grade 5 15-53µm

Ta 15-53µm

Thermal Spray Powders

By utilising advanced Gas Atomisation and VIGA Technology and sustainable processes, we supply a wide range of spherical nickel-based, cobalt-based & iron-based powders for the techniques:

- Oxy-Acetylene Spraying

- Plasma Spraying

- Plasma Transferred Arc (PTA) Weld Deposition

- High-Velocity Oxy-Fuel (HVOF) Spraying

- Laser Cladding

- The full range of powders feature high spherical degree, low oxygen levels and high crack resistance.

View our powder products & specifications here

Diamond Tool Powders

As the pioneer in the field of manufacturing micron-sized, ultrafine pre-alloyed powders using hydrometallurgy technologies, we have over 15 years of experience in the metal powder industry. By continuously focussing on R&D, rigorously studying the characteristics of diamond tools and satisfying the high standards of countless matrix powder customers, we have established a solid global reputation.

We manufacture 4 series of matrix powder including:

- Ultrafine Cobalt-free Pre-alloyed Powders

- Ultrafine Cobalt-based Pre-alloyed Powders

- Ultrafine Laser Welding Pre-alloyed Powders

- Ultrafine Free Sintering Pre-alloyed Powders

All products feature highly porous morphology, high sintering activity, greater homogeneity, excellent metal distribution, higher protrusion, stronger diamond retention and remarkable cold pressing ability, etc.

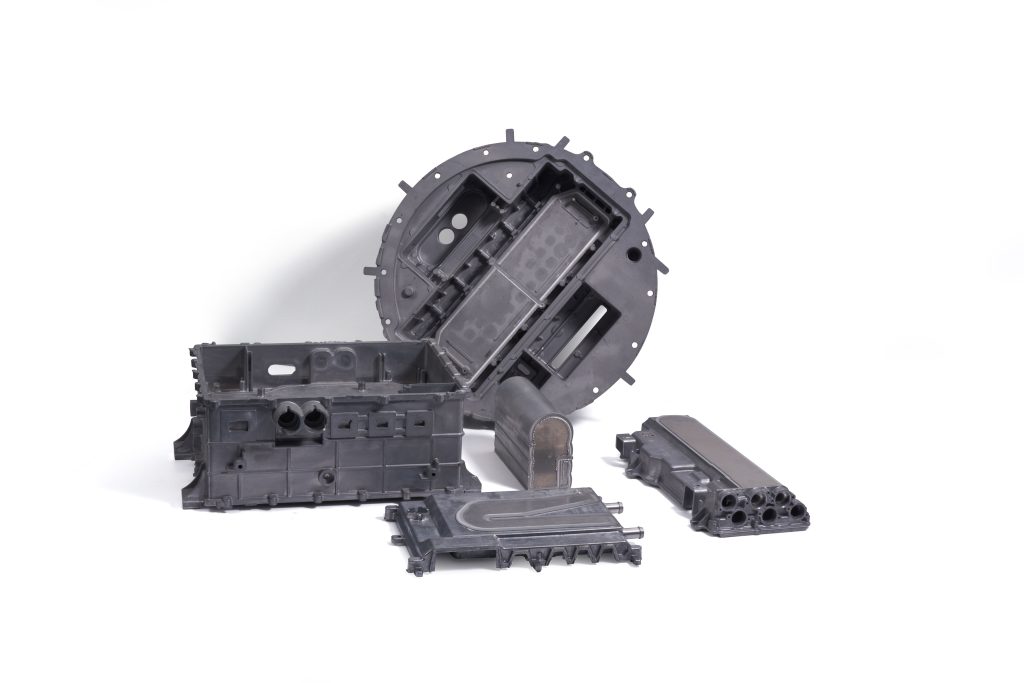

Friction Stir Welding Solutions

FSW Welding Technology Co. is a leading high-tech company which provides services of advanced friction stir welding (FSW) technology, product processing, machines, product development and technical training.

Based on the combination of advanced FSW theory, engineering application and high precision machine manufacturing, FSW Welding Technology developed various types of high-tech FSW machines including moving gantry machines, gantry-type FSW machines and robotic FSW systems. A set of operating systems specialised for friction stir welding have been developed based on the Siemens 828D system in addition to years of R&D and FSW experience. The NC system offers automation, intelligence and high reliability through deep secondary development, which provides strong guarantees for the automation of FSW process. Every machine can be directly connected to the client-side via mobile or tablet, providing real-time data from the welding machines aiding the delivery of after-sale service and technical support. According to customer requirements, customised operating systems are provided with special functional modules such as piecework, FSW tool life evaluation, traceability of FSW processing data and parameters creating comprehensive supervisory control.

FSW Welding Technology also developed top-level tailor-made tools which have gained numerous national patents. The company was the first in China to apply Stationary Shoulder FSW on the battery trays of electric vehicles by conventional Gantry Type FSW machine. The new technology greatly improved automated production processes, increased output and reduced costs. Single-side aluminium alloy up to thickness of 50mm can be welded.

With customer satisfaction as its core value, FSW Welding Technology provides full process service including product design, technical demonstrations, product trial manufacturing, small batch production, mass-production, FSW technique and machine turnkey project and after-sale technical support.

Refractory Materials & Parts

Partnering with the globally-leading refractory metal materials and parts manufacturers, we provide a wide portfolio of advanced products.

- Sintered Tungsten, Molybdenum & their Alloys

- Tungsten Heavy Alloys

- Rolled & Forged Tungsten & Molybdenum Products

- Tungsten (Molybdenum) Copper Alloys

- Tungsten Electrodes for TIG Welding

- Molybdenum Sputtering Targets

- Rhenium & Rhenium Alloys

- Tantalum & Tantalum Alloys

- Advanced Ceramic Powder & Products

Our products are widely applied not only in the traditional industries such as aviation, aerospace, automobile, electronic and electric power, equipment manufacturing, metal material processing, quartz and glass fibre manufacturing, high-temperature industrial furnaces and electric light sources, but also in new fields such as LCD, solar energy, nuclear energy, LED lighting, large-scale integrated circuits, new energy vehicles and consumer electronics.